|

Brand |

Pramet |

|

Chipbreaker |

SI |

|

Clearance Angle |

7° |

|

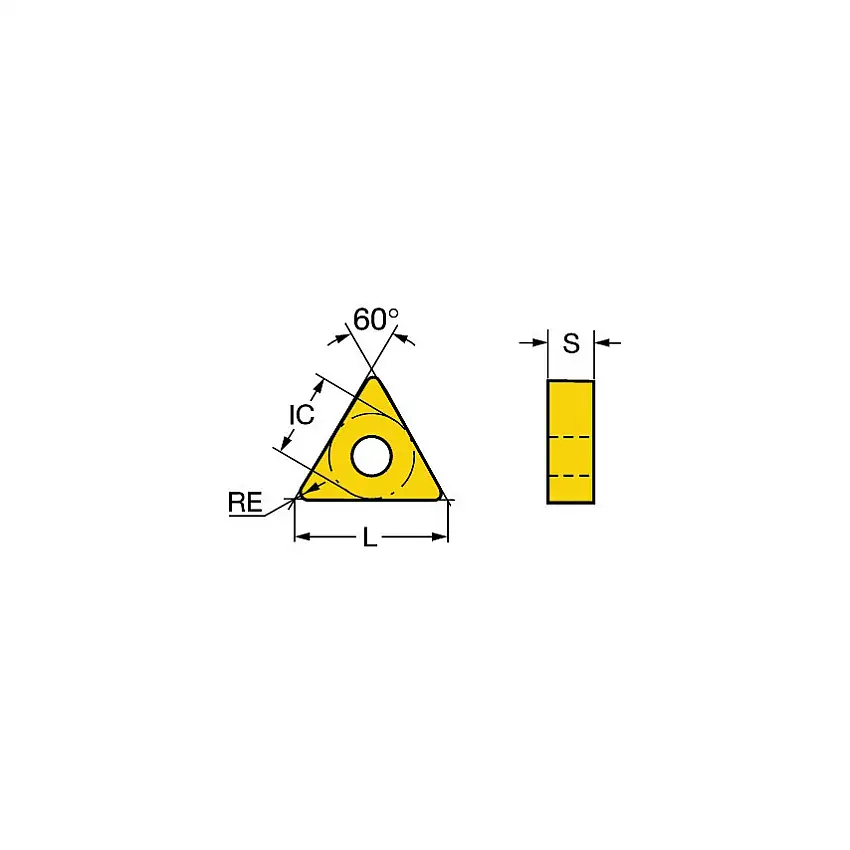

Corner Radius |

0.2mm |

|

Cutting Direction |

Right Hand |

|

Cutting Edge Length |

6.4mm |

|

EAN |

3603603817913 |

|

ECLASS Code |

21010901 |

|

Finish/Coating |

PVD |

|

Inscribed Circle |

6.35mm |

|

Insert Size |

06 |

|

Insert Style |

CCGT |

|

ISO Cut |

M20-M35 P20-P40 |

|

ISO Designation |

CCGT060202ER-SI:T8430 |

|

Manufacturer Grade |

T8430 |

|

Material |

Carbide |

|

Material Application |

Steel |

|

MFR Part No. |

7977180 |

|

Pack Quantity |

1 |

|

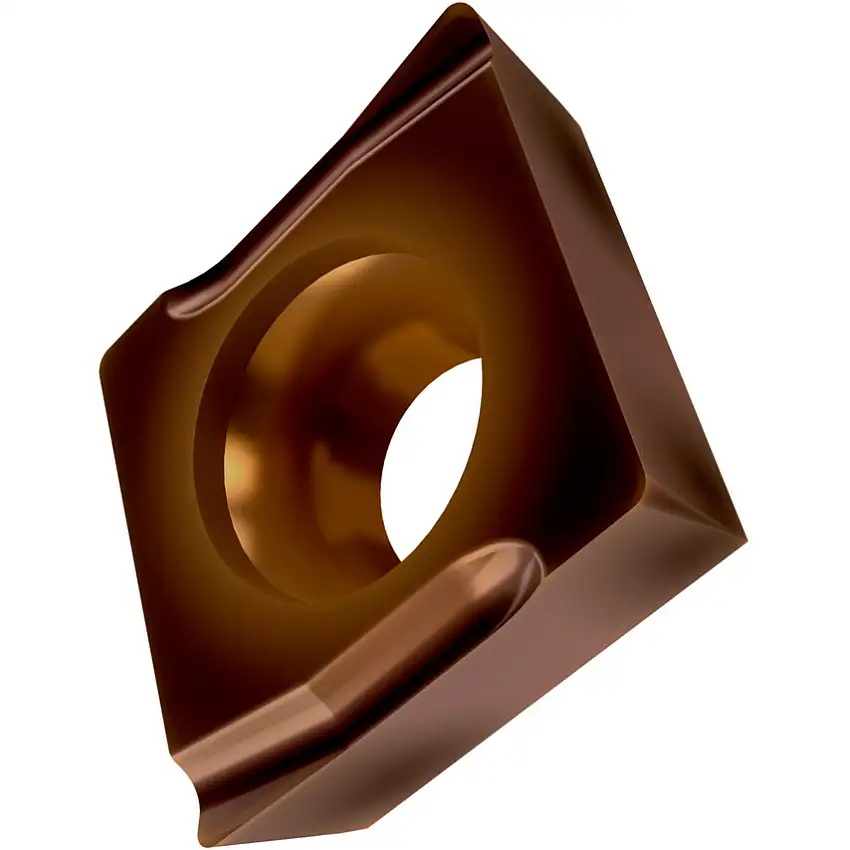

Shape |

80° Rhombic |

|

Thickness |

2.38mm |

|

UNSPSC Code |

23101511 |

Elevate precision in fine to medium machining of steel and stainless steel with the single-sided 80° rhombic turning insert. Available in both left and right-handed variants, the PVD-coated fine-grained WC-Co carbide cuts within ISO ranges P20 – P40 and M20 – M35 for smooth and efficient turning operations.

Features and Benefits

- Smooth machining facilitated by rounded edges, omitting T-land, with light feed and shallow depths of cut, ensuring ample edge strength while mitigating work-hardening risks

- 3-D chip-breaker guarantees effective chip control across a broad spectrum of feeds and depths, to enhance performance

- Wide chip groove enhances chip control in challenging materials, promoting improved chip evacuation during machining

- WC-Co-based substrate, submicron-grained, delivers superior hardness, abrasive wear resistance, and resistance against comb cracks

- PVD coating enhances resistance to thermal cracking, ensuring optimal performance in operations with varying cutting temperatures

- Multi-layered PVD coating, features a thick TiN layer for crater wear resistance and a hard AlTiN layer for flank wear resistance

- Unique Titanium-Boron-Nitride (TiBN) top layer reduces build-up edge and enhances overall performance

Typical Applications

- Steels

- Stainless steel

Reviews

There are no reviews yet.